✆ + 1-646-235-9076 ⏱ Mon - Fri: 24h/day

5 months

Project duration

Outsource

Engagement model

4 Developers

Team size

UK

Client

Project Introduction

In the realm of precision depth measurements, our project aims to revolutionize and streamline the processes involved through the “DepthMetrics Automation Initiative.”

DepthMetrics proposes a comprehensive solution to enhance efficiency, accuracy, and user flexibility in depth measurement procedures.

To ensure seamless data processing and storage from the encoder, the project recommends the utilization of a specialized Siemens PLC (Programmable Logic Controller) equipped with high-frequency input capabilities. This PLC acts as the central hub for data management, offering reliability and precision.

The PLC is outfitted with a Human-Machine Interface (HMI) panel, providing users with an intuitive platform to customize PLC programs for different encoders on-site. This user-friendly interface enhances adaptability and ease of operation, allowing for quick adjustments as per the specific requirements of the depth measurement task.

High-speed data from the encoder is efficiently processed by the PLC and wirelessly transmitted via a Wi-Fi access point. This data streaming functionality eliminates the need for local internet connectivity, offering a flexible and portable solution for depth measurement tasks.

The PLC module incorporates an external “Zero Point” button, a crucial feature for accurate depth measurements. When the drilling equipment is positioned at the starting level, users can simply press the zero button to establish a reference point. This initiates further measurements with precision and consistency.

By combining Siemens PLC technology, user-friendly interfaces, wireless data streaming, and zero-point calibration, the DepthMetrics Automation Initiative represents a significant leap forward in automating depth measurement processes. This project not only enhances the accuracy of measurements but also empowers users with a versatile and efficient tool for diverse applications in drilling and related industries.

Scope of Project

1. Mobile app development

– Design and develop an Android app to receive and display data from the PLC.

– Implement features for real-time monitoring and control.

– Test the app for compatibility with different devices and encoders.

2. Wireless Communication development

– Establish a reliable Wi-Fi connection for data streaming from the PLC.

– Develop a secure and efficient protocol for wireless data transmission.

– Ensure compatibility with the Android app for seamless integration.

3. Project management

– Develop and oversee the project plan, timeline, and budget.

– Coordinate communication and collaboration among team members.

– Monitor progress and address any issues that may arise.

– Ensure that the project stays aligned with the overall goals and objectives.

4. Quality Assurance

– Conduct thorough testing of the entire system to identify and rectify any bugs or issues.

– Perform integration testing to ensure all components work seamlessly together.

– Validate the accuracy of depth measurements under various conditions.

Project’s Specifics

Results

1. Improved Efficiency

– Streamlined data processing through the Siemens PLC and user-friendly HMI panel will significantly enhance the efficiency of depth measurements.

– Quick adjustments using the HMI panel for different encoders will reduce downtime between tasks.

2. Enhanced Accuracy and Precision

– The integration of a high-frequency input Siemens PLC ensures accurate processing and storage of data from the encoder.

– The “Zero Point” calibration feature facilitates precise measurements by establishing a reference point for each operation.

3. User Flexibility

– The HMI panel allows users to easily customize PLC programs, providing adaptability for varying site conditions and different types of encoders.

– Wireless data streaming to the Android app enables users to monitor and control depth measurements remotely, enhancing flexibility in operation.

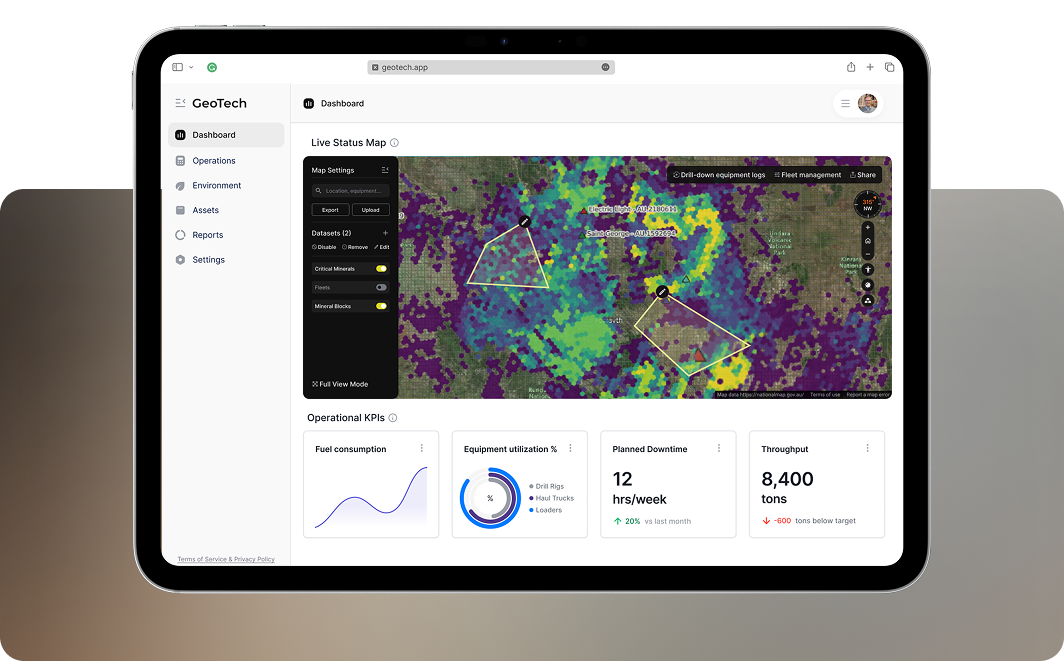

4. Real-time Monitoring and Reporting

-The Android app facilitates real-time monitoring of depth measurements, allowing users to make informed decisions on-site.

– The system generates reports that can be accessed and analyzed for historical depth measurement data.

5. Portability and Connectivity

– The wireless data streaming feature eliminates the need for local internet connectivity, making the system highly portable and suitable for diverse working environments.

– Compatibility with Android devices ensures widespread accessibility for monitoring and control.

6. Reduced Manual Intervention

– The automated processes, including data processing, streaming, and zero-point calibration, reduce the need for manual intervention, minimizing the risk of errors and improving overall safety.

7. Comprehensive System Reliability

– Thorough testing and quality assurance measures ensure the reliability and stability of the entire system, providing users with a dependable tool for depth measurements.

8. User Empowerment and Training

– Training materials and documentation empower users to effectively operate and leverage the capabilities of the automated depth measurement system.

– Ongoing support mechanisms ensure users can confidently use the system and troubleshoot issues as needed.

9. Positive Impact on Industry Practices

– The successful implementation of the DepthMetrics Automation Initiative is expected to set a benchmark for modernizing depth measurement practices in drilling and related industries.

– The project may pave the way for similar automation initiatives in other areas of industrial processes.

Similar Case Studies

Contact Us

New York

348 W. 57th St., New York, NY 10019

+16462359076

contact@fordewind.io

Vancouver, Canada

W Georgia St, Vancouver, Canada

+16047649232

contact@fordewind.io

Warsaw, Poland

Plac Europejski 4, Warsaw, Poland

+48452478282

contact@fordewind.io

Tallinn, Estonia

Kesklinna linnaosa, Kaupmehe, 10114, Estonia

contact@fordewind.io

Kyiv, Ukraine

19 Koval’s’kyi Lane, Kyiv, Ukraine

+380967764322

contact@fordewind.io