✆ + 1-646-235-9076 ⏱ Mon - Fri: 24h/day

5 months

Project duration

Outsource

Engagement model

7 Developers

Team size

Germany

Client

Project Introduction

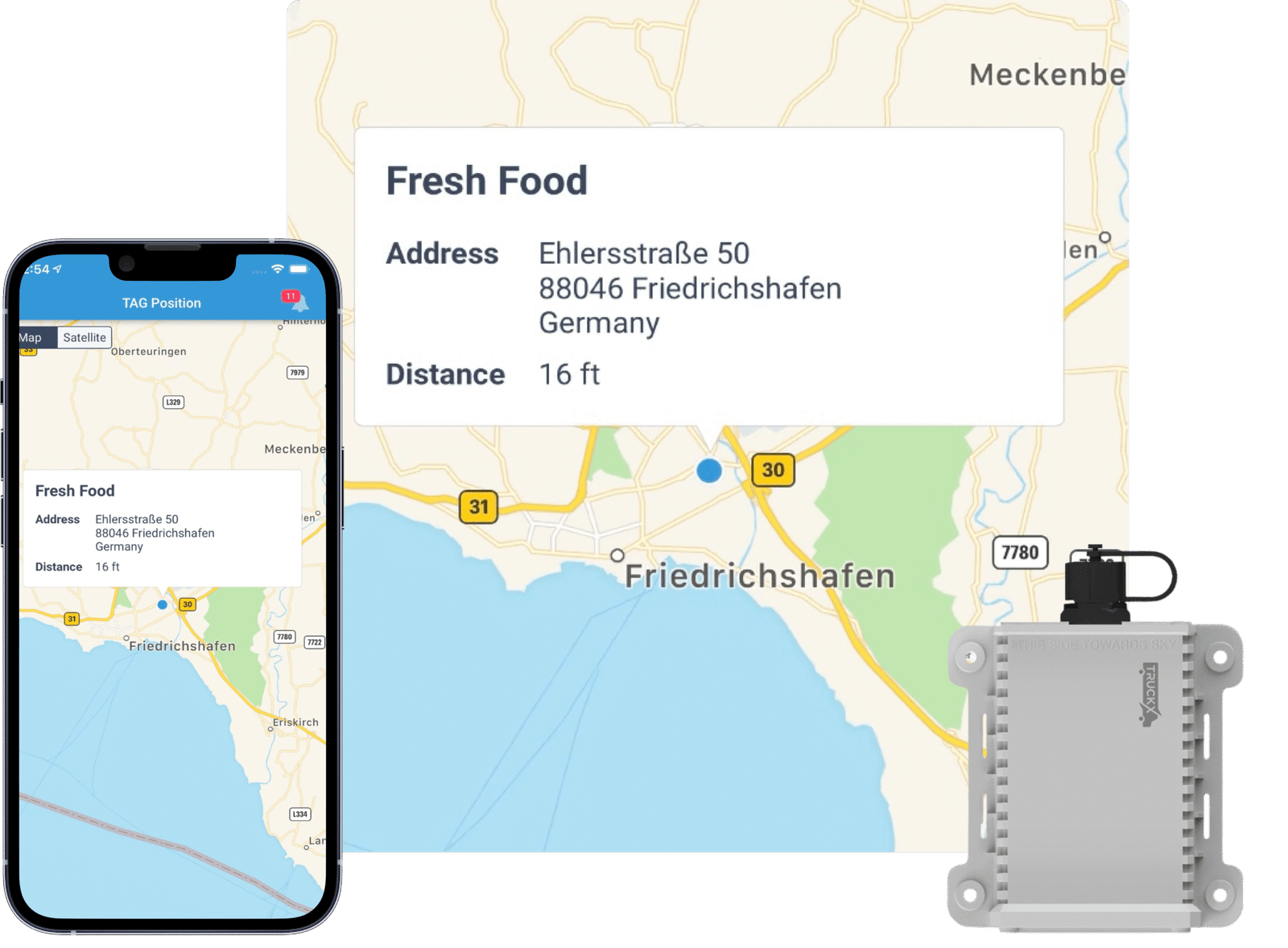

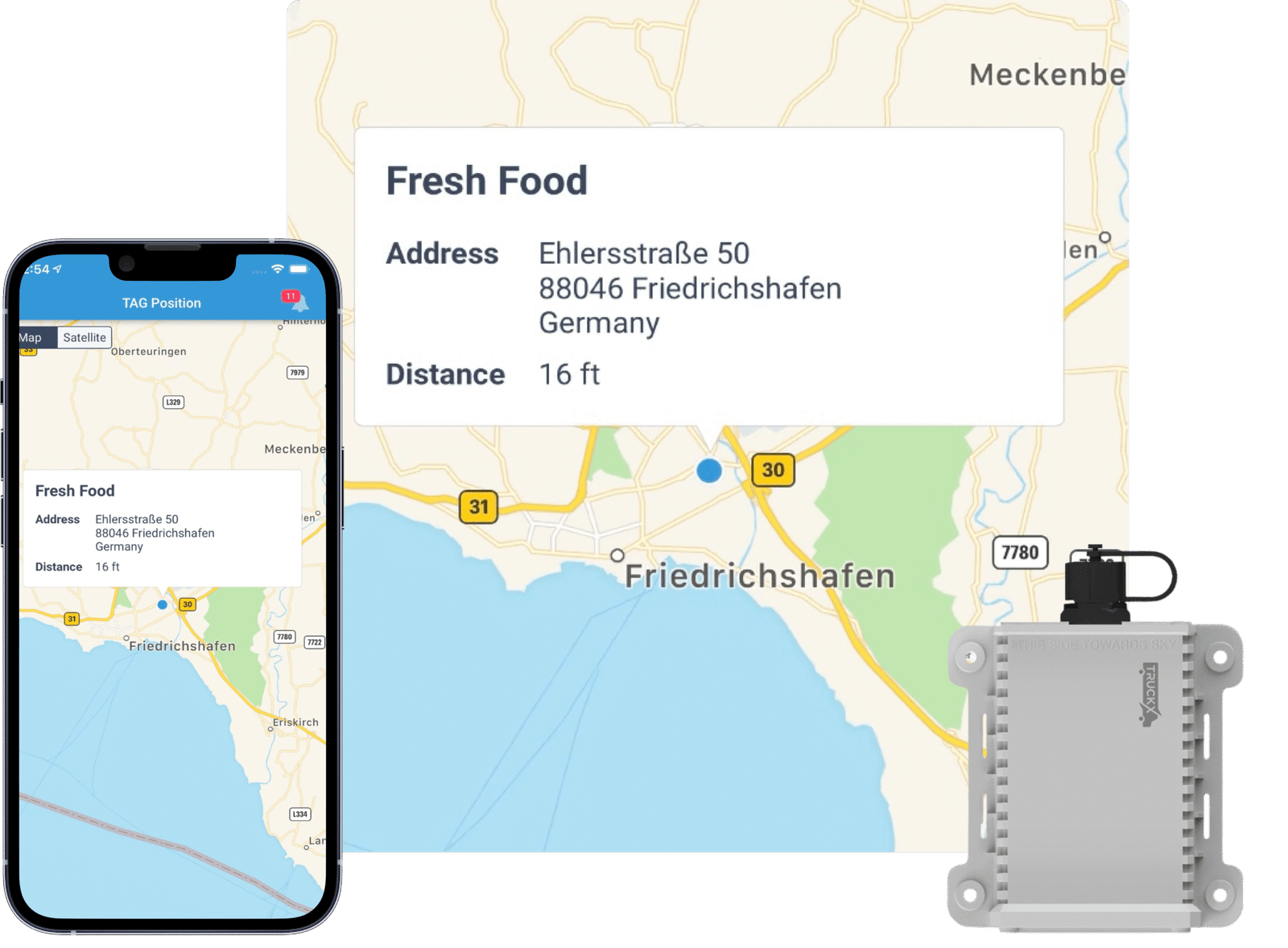

The Smart Asset Tracking System is a revolutionary technology that transforms the logistics and supply chain industry. It introduces an advanced infrastructure that facilitates real-time monitoring and management of assets. The system uses Bluetooth Low Energy (BLE) tags, RFID (Radio-Frequency Identification), GPS (Global Positioning System), or a combination of these technologies to enable real-time tracking and data collection. The BLE tags act as intelligent beacons, providing precise and efficient tracking of assets throughout the supply chain.

These BLE tags communicate seamlessly with a Mobile App, creating a dynamic and interconnected system that is compatible with both Apple and Android devices. The app provides users with real-time data and analytics, allowing for comprehensive insights into the location, status, and condition of assets.

The Smart Asset Tracking System is more than just a tracking tool. It offers a comprehensive solution for optimizing logistics and supply chain operations. By providing visibility into the movement of assets, companies can address potential bottlenecks, enhance resource allocation, and streamline their overall operations. The system’s versatility extends to various industries, from manufacturing and warehousing to transportation, ushering in a new era of efficiency and productivity in the world of supply chain management.

Scope of Project

1. BLE (Bluetooth Low Energy)

– Develop and implement BLE technology to enable seamless communication between tracking devices (tags) and the central system.

– Optimize BLE functionality for efficient and low-power data transmission, ensuring extended battery life for tracking devices.

2. Architecture Design

– Design the overall architecture of the Smart Asset Tracking System, defining the structure and interconnections between components.

– Consider scalability, flexibility, and reliability in the architecture to accommodate future expansion and evolving technological requirements.

3. On-Board Unit Software Development

– Develop the software embedded in the onboard units or tracking devices, ensuring they can accurately collect and transmit data.

– Implement features such as real-time location tracking, status monitoring, and data encryption to secure the information being transmitted.

4. Quality Assurance

– Conduct thorough testing of the entire system, including hardware and software components.

– Ensure the reliability and accuracy of data collected by tracking devices and validate the functionality of the BLE communication protocol.

5. Big Data Analysis and Reporting

– Implement data storage and retrieval mechanisms capable of handling large volumes of data generated by the tracking devices.

– Develop algorithms for real-time analysis of big data, extracting meaningful insights and patterns related to asset movement and usage.

– Design reporting mechanisms to present actionable information to end-users, facilitating decision-making.

6. Project Management

– Oversee the entire project lifecycle, including planning, scheduling, and resource allocation.

– Coordinate the efforts of different teams working on BLE implementation, architecture design, software development, quality assurance, and data analysis.

– Ensure the project stays on schedule, within budget, and meets predefined milestones.

– Facilitate communication between teams and stakeholders to address challenges and keep everyone aligned with project goals.

Project’s Specifics

Results

1. Efficient Logistics Routes

One of the primary problems that the system addresses is the need for efficient logistics route planning and monitoring. By equipping assets, vehicles, and goods with BLE tags, companies gain granular control and monitoring capabilities. This translates into optimized routes, reduced transit times, and ultimately, significant cost savings.

2. Cost-effective Synchronization:

Supply chain departments often operate in silos, leading to inefficiencies and miscommunication. The system offers a cost-effective way to synchronize various supply chain departments by providing real-time asset location and status information. This fosters improved collaboration and coordination among teams, resulting in smoother operations and lower operational costs.

3. Goods and Condition Monitoring

Monitoring the condition of goods during transit is crucial to ensure their quality upon delivery. Companies can continuously track the condition of goods, such as temperature, humidity, and shocks. This proactive monitoring helps prevent damage, spoilage, or quality issues, enhancing customer satisfaction and reducing financial losses.

4. Vehicle Maintenance Optimization

Vehicle maintenance is a significant cost for logistics companies. The system assists in optimizing vehicle maintenance by providing real-time data on vehicle performance. This allows for predictive maintenance scheduling, reducing the likelihood of unexpected breakdowns and minimizing downtime.

5. Real-time Data Analytics

The system offers real-time data analytics through a cloud platform. This data-driven approach enables companies to make informed decisions, identify areas for improvement, and respond quickly to changing conditions in the supply chain.

6. Reduction of Fuel Emissions

Optimizing routes and vehicle maintenance contributes to a reduction in fuel emissions. This is not only environmentally responsible but also aligns with corporate sustainability goals and may lead to potential regulatory incentives.

7. Saved Funds for Operational Processes

The predictive maintenance capabilities of the system, coupled with efficient route planning and condition monitoring, lead to significant savings in operational processes. Companies can reduce unnecessary maintenance costs, prevent costly delays, and improve overall operational efficiency.

Similar Case Studies

Contact Us

New York

348 W. 57th St., New York, NY 10019

+16462359076

contact@fordewind.io

Vancouver, Canada

W Georgia St, Vancouver, Canada

+16047649232

contact@fordewind.io

Warsaw, Poland

Plac Europejski 4, Warsaw, Poland

+48452478282

contact@fordewind.io

Tallinn, Estonia

Kesklinna linnaosa, Kaupmehe, 10114, Estonia

contact@fordewind.io

Kyiv, Ukraine

19 Koval’s’kyi Lane, Kyiv, Ukraine

+380967764322

contact@fordewind.io